High Temperature and Humidity Test & Low Temperature Test

This is a pre-test to ensure that the use of the product is not affected by poor conditions such as hot, humid, and cold areas.

| Test | Standards |

|---|---|

| High Temp. Test | Leave the product at 60±3℃ condition for 48hours and has to be normal functioning within 5 minute in room temp. |

| High Humidity Test | Leave the product at 90% +2/-3 condition for 48hours and has to be normal functioning within 5 minute in normal humidity |

| Low Temp. Test | Leave the product at 60±3℃ condition for 48hours and has to be normal functioning within 5 minute in room temp. |

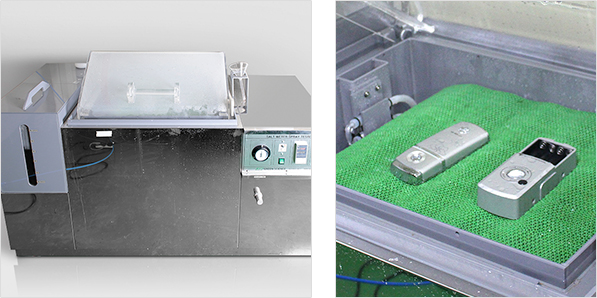

Salt spray test

Test of how much salt wind or saline fog affects the product’s corrosion resistance of metal materials (the degree of corrosion) and circuits, etc. to secure the reliability of the product.

| Test | Standards |

|---|---|

| Saline Concentration | 50% ± 0.5% |

| Chamber Temperature | 35℃ ± 2℃ |

| Spray pressure | 0.7 ~ 1.8 Kg/cm2 |

| Sprayed capacity | 1.0 ~ 2.0㎖ / 80 cm2/hr |

| Test hour | 72hr |

Condensation test

This is a pre-test to identify and compensate for the effects of condensation on the product.

Rubbing Alcohol test

This test verifies abrasion resistance of the surfaces of various parts, such as painting, coating, printing, etc. This is a pre-test to maintain a constant look quality for long-term use because there will be lots of contact with human hands during operation.

| Test Condition | Company’s standard |

|---|---|

| alcohol Concentration | Ethyl alcohol 94% |

| Pressurized Load | 1Kg |

| Speed | 65 times / min |

| STROKE | 30 mm |

| Back-and Forth | 200 times |

| Standard | No exposure of low material |